One Simple Ingredient

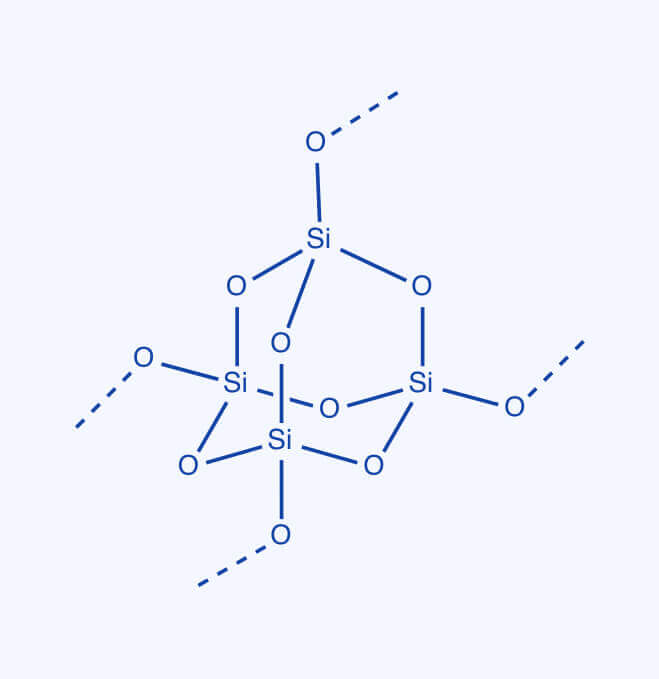

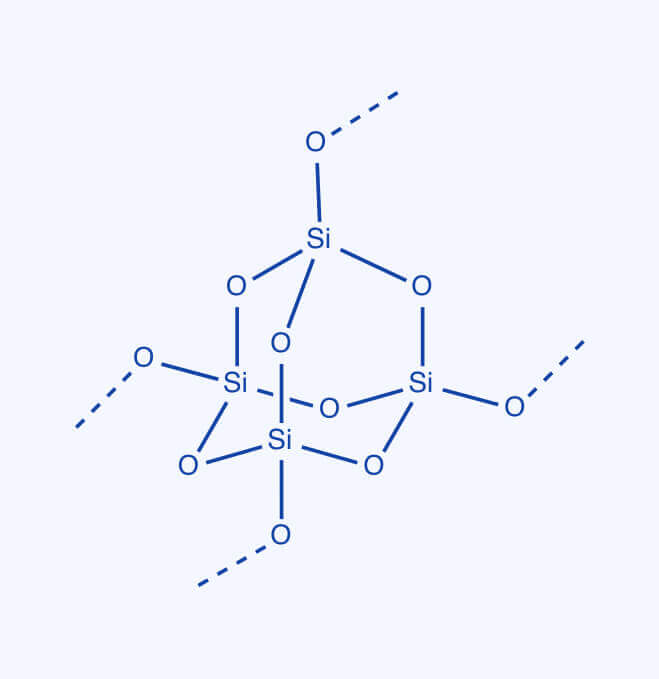

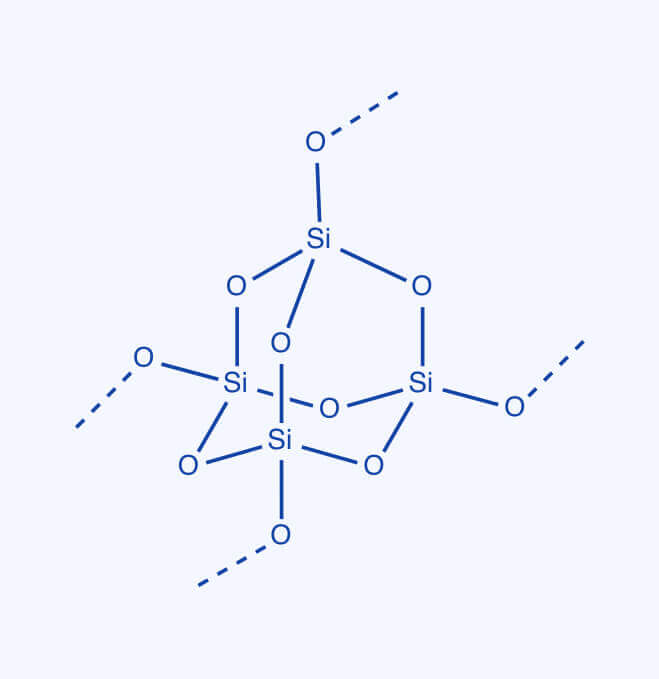

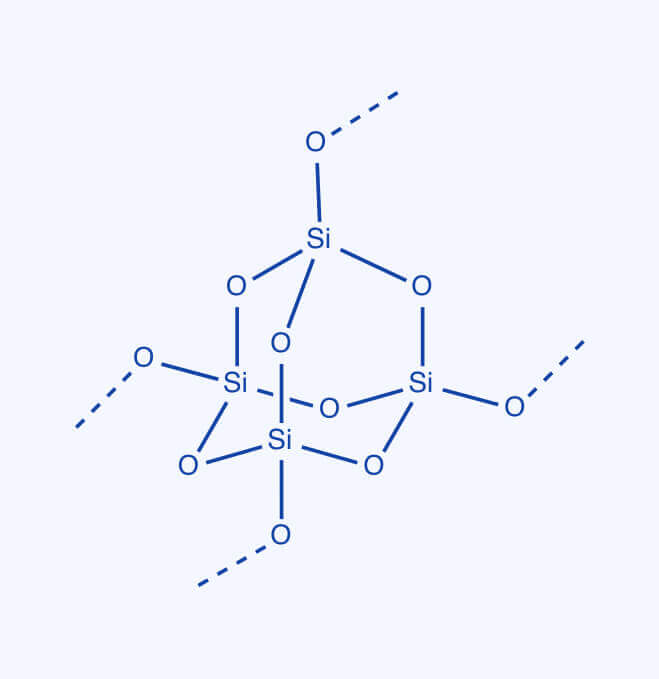

Colloidal silica consists of nano-scale silica particles, predominantly Silicon Dioxide (SiO2), dispersed in a

liquid medium. Through refining silica sand, we meticulously disperse and stabilize SiO2 particles within the

liquid to achieve a consistent and stable colloidal mixture. Our technique ensures that the colloidal silica has an

even particle size distribution, making it ideal for a variety of applications such as a binder, surface modifier,

flocculant, and more.

Many

Nuances

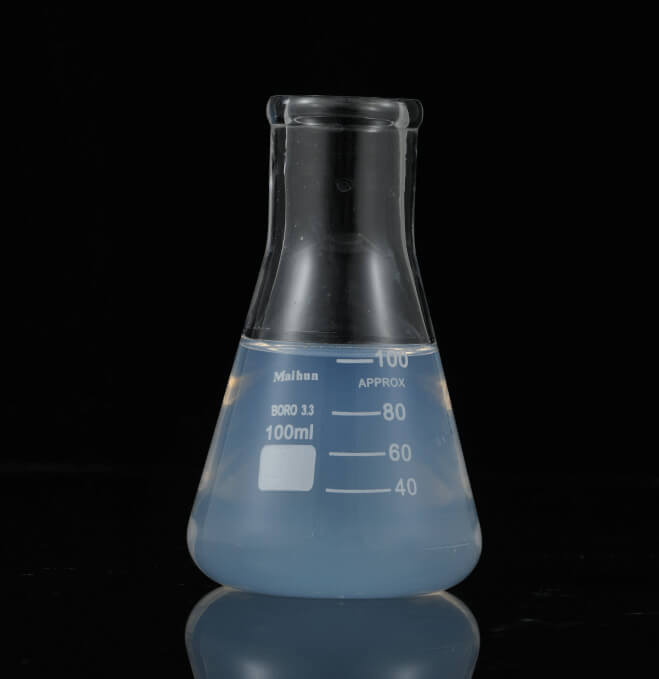

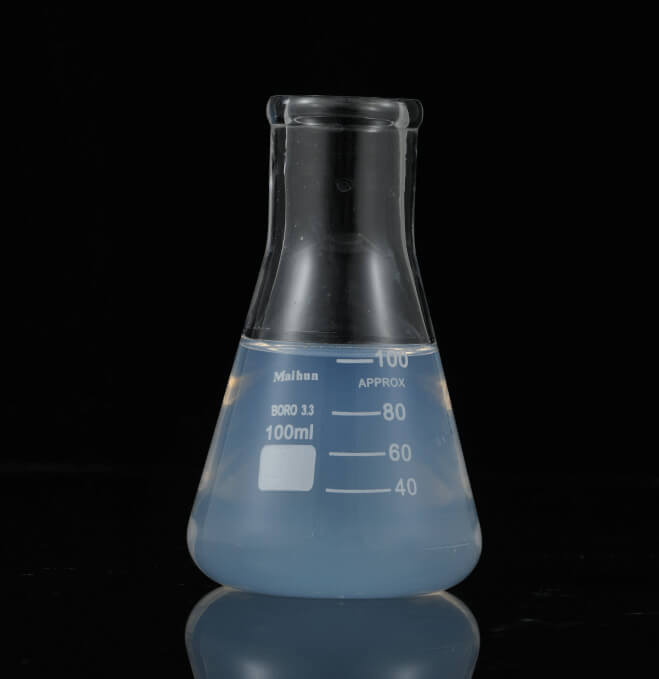

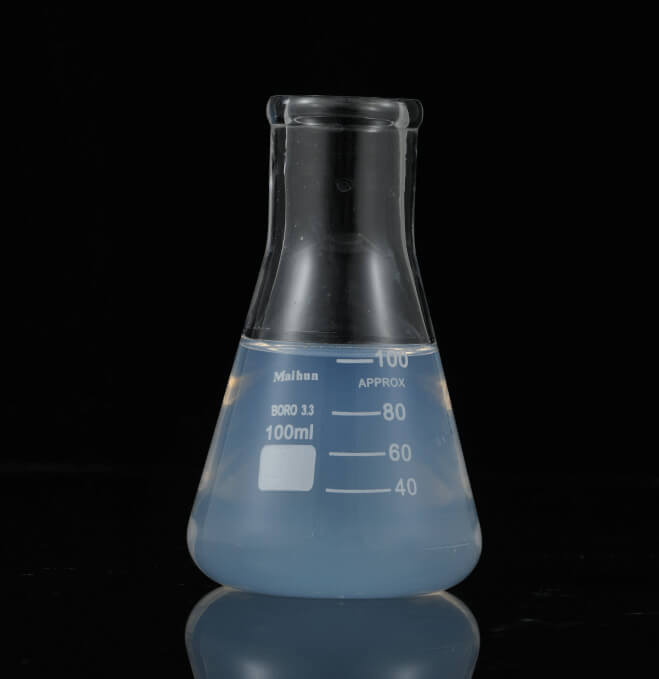

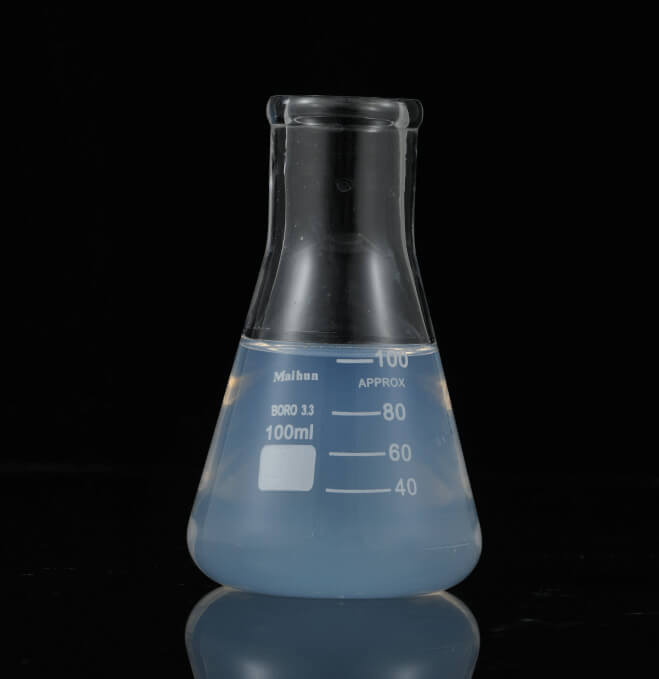

Even subtle differences in colloidal

silica properties can significantly impact its applications. Advent Silica’s product portfolio

offers a wide range of products that encompass a broad spectrum of these properties.

The pH value determines the surface charge and

stability of the colloidal silica particles, influencing their interactions and

dispersion behavior. Controlling the pH allows precise manipulation of colloidal

stability and surface properties.

Advent Silica offers

various lines of alkaline, acidic, or near-neutral colloidal silica solutions,

catering to different applications.

Smaller particle sizes of colloidal silica offer a

larger surface area, resulting in increased reactivity, adsorption capacity, and

enhanced stability. Conversely, larger particles provide improved mechanical

reinforcement, filling, and controlled release capabilities.

Advent Silica has the capability to customize particle

sizes ranging from 3nm to 180nm.

The concentration of silica affects various aspects,

including viscosity, stability, and performance in different applications. Higher

concentrations often lead to increased viscosity and improved binding or reinforcing

properties.

Advent Silica’s product offerings provide a

range of tailored concentrations from 15 to 50%.

Stabilizing ions, such as sodium or ammonium ions,

play a role in maintaining colloidal stability by preventing particle agglomeration and

maintaining the desired dispersion.

Advent Silica offers

ammonium-stabilized solutions in situations where the use of sodium stabilizing ions

is to be avoided.

Learn more about featured products

Infinite Potential

The remarkable properties of colloidal

silica empower various sectors to achieve enhanced durability, precise surface finishes, and

improved performance, among other benefits.

Colloidal silica’s outstanding stability makes it

suitable as a binder in investment casting, coatings, a catalyst support in chemical

reactions, and a polishing agent for precision surfaces.

The controlled particle size distribution enables

precise customization of materials and structures, resulting in specific optical

properties, mechanical characteristics, and printing behavior in various applications.

With its high surface area, colloidal silica

enhances adsorption capacity, making it valuable in wastewater treatment, adhesives,

ceramics, as well as cosmetics.

Colloidal silica’s exceptional stability, controlled

particle size distribution, and high surface area enable diverse uses, from acting as a

binder in investment casting and coatings to catalyst support in chemical reactions, and

enhancing adsorption capacity in wastewater treatment, adhesives, ceramics, and

cosmetics.

Learn more about featured applications

+1 973-449-3371

+1 973-449-3371

sales@adventsilica.com

sales@adventsilica.com

BROCHURE

BROCHURE

CONTACT US

CONTACT US